HERRING

***

biodiesel - diesel stove / natural draft = non electric.

Specifications:

- Dimensions: 12”

Wide x 13” Deep. (31 x 33Cm)

Plus 3" to Right to operate Burner Stem Cleaning Rod.

26-1/4"

to top of cook surface with legs.

Legs are 3” High.

28” to top of stainless sea rail.

(71Cm)

- Weight: 55

Lbs. (25 Kg)

Minimum space required is 15" in width by 14" in depth.

This does NOT take into consideration the space required

for shielding surrounding combustibles.

Features:

- Best European Blue Flame Burner Optimized for Biodiesel.

- Optional: Pair of Internal,

Sepentine Hot Water Heat Exchangers.

- Heavy cast iron & stainless steel construction (sides & back are

SS).

- For Biodiesel or Petrol Diesel. (no solid fuels)

Flowrate: 8 oz./Hr. Low to 24 oz./Hr. High.

(.031 Gal./Hr. to .1875

Gal./Hr.)

- High Temperature Glass Window.

- Stainless or Upgrade

Brass Sea Rail.

- Uses 4" Chimney Pipe (10 Cm).

- Approx. Max. Output: 20,000 Btu’s.

- Compatible with our bronze "Drop-In" Burner Modules!

Pricing:

$3385 / With High Temp Paint

Porcelain Enamel Option / CALL

Yes, it's a tall stove which happens as a result of the burner's flame pattern.

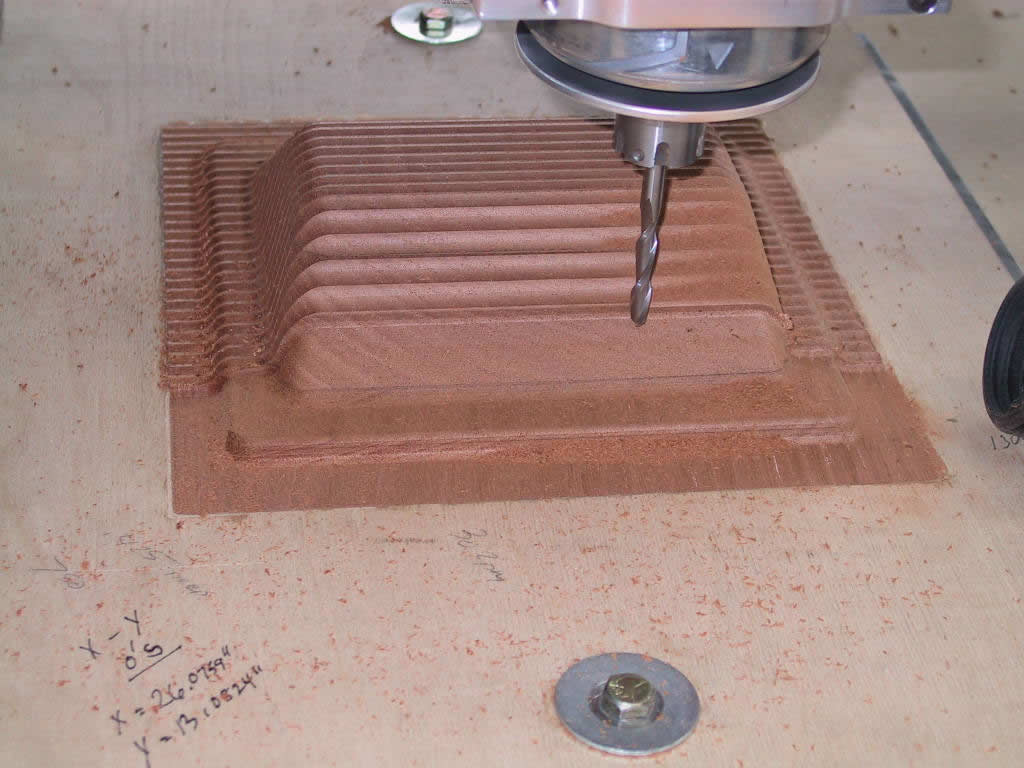

CNC machining a mahogany foundry patern used for the stove's exhaust.

The router is used for general pattern work and for our customized foam packing materials.

***

Now, a little somethirter. Sometime's I'll a

360 298 4623 / andrewmoore@marinestove.com